Equipment used: Thermal imaging, tracer gas, endoscope survey, moisture meter profiling and visual inspections.

Upon arrival a visual inspection was carried out throughout the property. Damage could instantly be seen on the kitchen flooring.

Moisture meter profiling was completed presenting a saturation of 999REL. However, on inspection there were no leaks to any of the above ground pipe works. In order to find the leak, we had to carry out a series of other tests.

What did we do next?

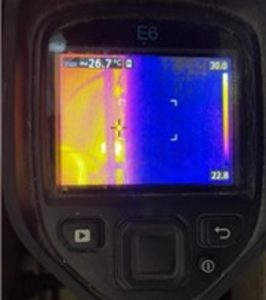

- A thermal imaging survey showed the hot water feed was constantly running and this was highlighted as an anomaly on our system.

- The endoscope survey behind the kitchen cabinets produced no pipe work located visually that accounted for the leak.

- From here an acoustic survey was carried out which you could hear the consistent sound which was exact to that of a leak.

To confirm our findings we concluded with a tracer gas survey on the hot water feed.

This was carried out at 2bar and a drop in pressure was observed within 15 minutes.

The areas that the internal hot feed run were all scanned for any escaping gas and we recorded high readings of 0.15 VOL behind the kitchen units.