Equipment used: Tracer gas, acoustic testing, thermal imaging, endoscope survey, moisture meter profiling and visual inspection.

When arriving at the property the damage could be seen on the walls and skirting in the living room.

Although the boiler doesn’t lose pressure, it is constantly calling for hot water. We carried out moisture meter profiling to the affect area which present fully saturated readings of 999REL.

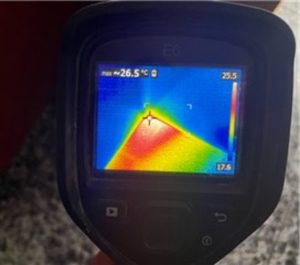

Through a thermal imaging survey, a thermal anomaly was located around the kitchen unit which could account to water damage/ ongoing leaks.

An endoscope survey was also carried out behind all the kitchen units and no pipework was located that could be leaking or accounting for the leak.

To confirm our findings, we completed a tracer gas survey to the internal hot feed. This was carried out at 2bar and a drop in pressure was observed within 15 minutes, indicating a leak.

The areas in which the internal hot feed ran were scanned and consistently readings of 38PPM were reported. These were found consistently at the back of the kitchen unit.